- Name of the project: “1.25: Research on development of mathematical model for silicon crystal growing technological process by using image processing methods.”- SikA

- Partners: KEPP EU

- Aim of the project: Czochralski silicon growing method is based on silicon melting, which is achieved either by heating the crucible with a powerful heating element or using the electron beam gun which heats and melts silicon.

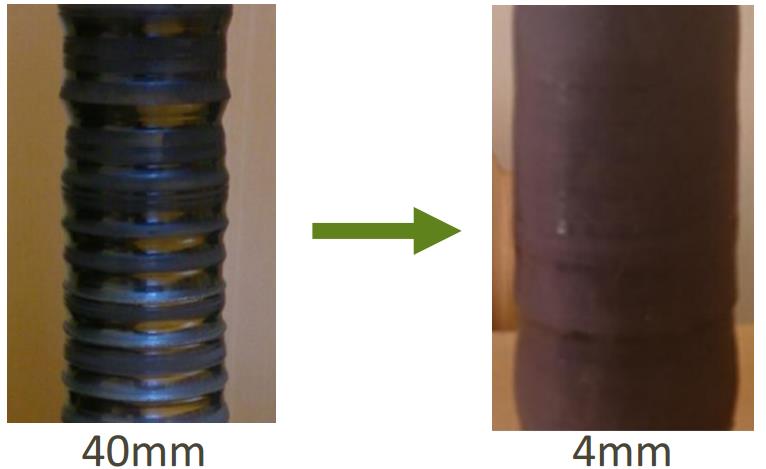

Electron beam gun ensures a lower energy consumption of one silicon ingot creation, but such processes are required to develop their own mathematical model to establish as accurately as possible ingot. From the formed ingot of accuracy depends on how much material will be mechanically separated from the ingot to create a cylinder. The more accurate grown silicon crystal ingot, less material will go to waste, and hence the electricity will be spent.

The project aims to explore importance of the silicon crystal growing process mathematical model modifiable parameters and stability of the crystal diameter, using an image processing technique by measuring the diameter of the silicon crystal and the electron beam gun power.

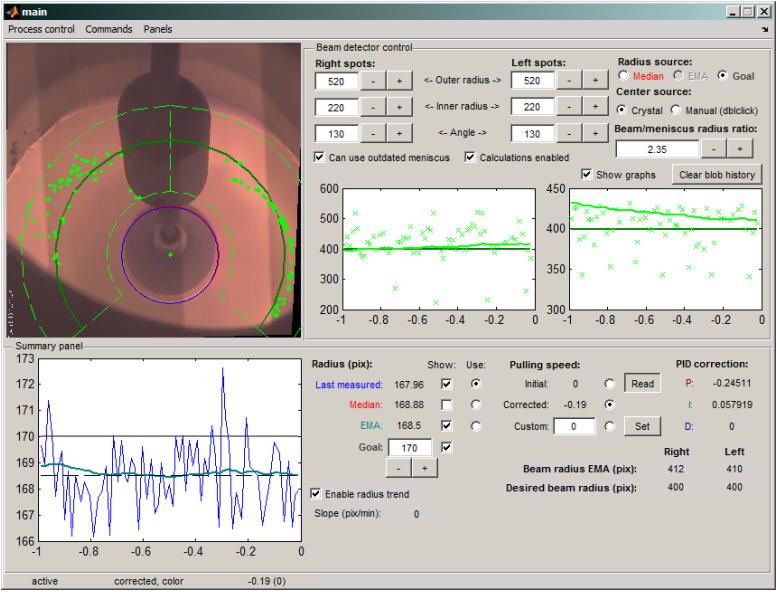

- Developed technologies: Software and grapgic user interface (GUI) for detection of crystal manic region and measurement of its radius; readout of the extraction rate; control of extraction rate using PID controller; determination of the path of motion of electron beams; calculation of radius trends; graphical representation of detected/read values; camera calibration; positioning and comparison of electron beam positions with a circular beam; Dummy-proof protection when changing settings; performing tests and reporting malfunctions; hardware interface via DAC / ADC / Modbus, camera via TCP / IP;

- Results achieved: The designed silicon crystal growing process mathematical model, which is based on the established image processing algorithm performing silicon crystal ingot diameter measurement and allows to adjust crystal ripping allowed to sabilize and minimize changes in crystal diameter from 40mm to 4mm.

See also in video: