Today, robots and other moving industrial equipment need to measure unusual vibrations and anomalies during their operation in order to be able

to act in time when the device is needed to be serviced. This helps to save funds that could be lost while production is halted.

The product includes an inertial sensor allowing measurement of the unit’s movement speed, angular acceleration and magnetic field strength.

When combining these parameters and combining them with algorithms, it is possible to determine the coordinates of the movement of the device

and to learn the nature of the vibrations in order to see the possible time and type of defect.

Depending on the configurations, data to the control system may be transmitted with very low delay (< 500 μs). The use of industrial environment friendly modulation

of radio waves (DSSS) is possible. Also high data transmission can be introduced (< 2Mbps), or, on the contrary, a very low throughput allowing the device to work for

a non-interruption of 1 year without charging.

Industrial wireless sensors are very handy because wired connections (power supplying, data transmission) in moving industrial equipment (CNC cutters, robotic hands) are

often not possible. Continuously transmitting data at 2Mbps allows sensors to run for 1 day without charging, therefore wireless charging is used for automated

operation, thereby providing uninterruptible activity without human intervention.

EDI Wireless Industrial sensors also include an external power supply (up to 0.5 A) and connectors that allow the power supplying and addition of external

sensors (gas, temperature, pressure, etc.), so that the measurements obtained are useful for a variety of industrial applications.

If the measurements are required to control/adjust the operation of the equipment, the assembly includes a receiver/gateway capable of controlling the

operation of the motors with a help of digital/analogue signal, handling and executing the algorithms, or simply visualizing the data on the screen with a USB connection.

You can configure sensors from a distance using an Android, Linux, or Windows 10 device. The user may choose and plan daily schedule in which the sensor will measure data or

ask the machine to return to the starting position for wireless charging. Depending on the configuration , the life cycle of the operation is modeled, helping to optimise

energy consumption and battery lifetime.

Configuration allows to change the accuracy, frequency and type of data measured, as well as adjust the radio transmission modulation, speed and latency.

Remote monitoring allows to check battery level, wireless charging speed/efficiency, and quality of radio transmission.

Key performance indicators:

– Bluetooth 5.0 radio

– 802.15.4 radio

– USB 2.0 Type-C connection/charging

– 550/1000 mAh battery included

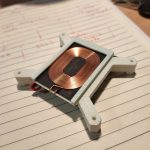

– An individual wireless charging solution

– 2MBPS data rate with Bluetooth 5.0 technology

– 250 Kbps data rate with 802.15.4 DSSS technology

– Internal inertial sensors

– External connecting sensors

– External supply (up to 0.5 A)

– “Full speed mode” – 1 day

– “Sleep mode” – 366 days

– Adjustable mounts

– 1 Physical push-button

– RGB LED indication

Contact information: