Klara Kuzņecova, a new researcher at the Institute of Electronics and Computer Science (EDI), was on a scientific mission in Poznań, Poland, from July 15 to September 15, at the Adam Mickiewicz University’s Center for Bionanotechnology, working closely with partners in the ESCULAPE project. The aim of the trip was to strengthen cooperation between EDI and AMU, improve practical skills, and evaluate the applicability and production improvement opportunities of the electrode prototype developed in the SUSTRONICS project.

During the trip, the focus was on materials science and bioelectronics, particularly the practical applications of MXene-type materials (e.g., Ti₃C₂Tₓ) in biosensors. MXene are innovative two-dimensional conductive materials with a large surface area to volume ratio, which determines their properties. The “Tₓ” functional groups allow precise adjustment of electrical conductivity, surface resistance, and contact properties on skin or hydrogels. In the case of electrodes, creating a smooth and sufficiently thin coating can reduce contact resistance and improve the signal-to-noise ratio in bioimpedance and biopotential measurements. Determining these parameters is important both in body composition analysis (determining bone, muscle, and fat mass) and in edema diagnosis.

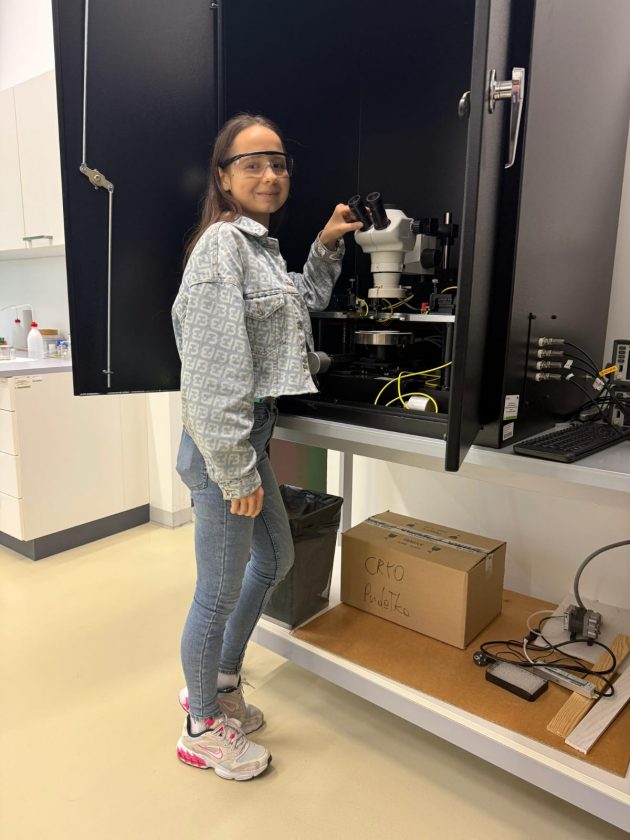

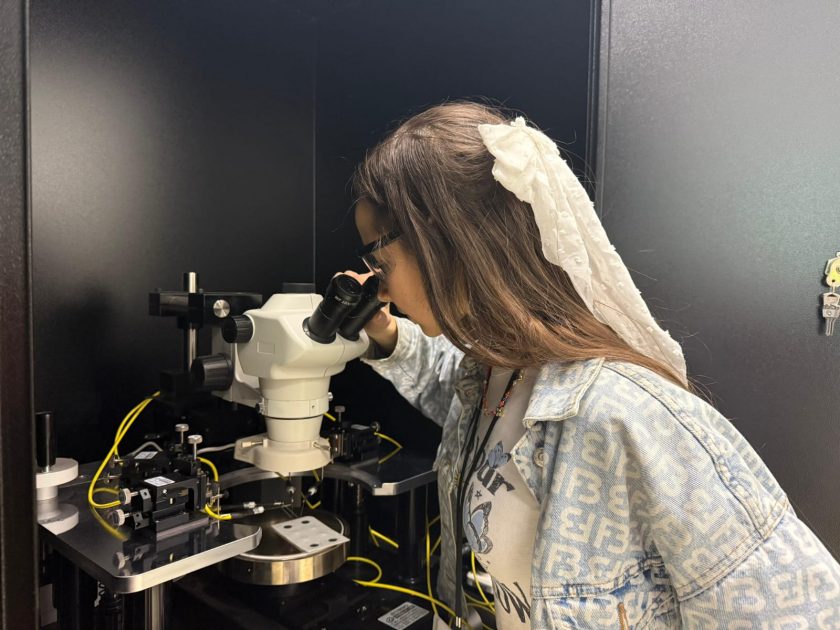

Upon arriving at the AMU Bionanotechnology Center, Klara and her colleagues were given a tour of the laboratory equipment and practical training. Under the supervision of scientists, she was able to perform tasks such as working with electron and ion microscopes (SEM/FIB) for surface topography and cross-section analysis, as well as learning the basics of crystallography with powder X-ray diffraction (XRD) to evaluate material phases. Klara also applied and improved her knowledge of electrochemistry, for example, by theoretically and practically researching the effect of solution parameters on MXene stability and electrode aging.

Secondly, Klara also learned about the production methods used at the Bionanotechnology Center, including electrospinning with PLA (polylactic acid) and other polymers for nanofiber formation, MXene synthesis and dispersion preparation, as well as bioprinting.

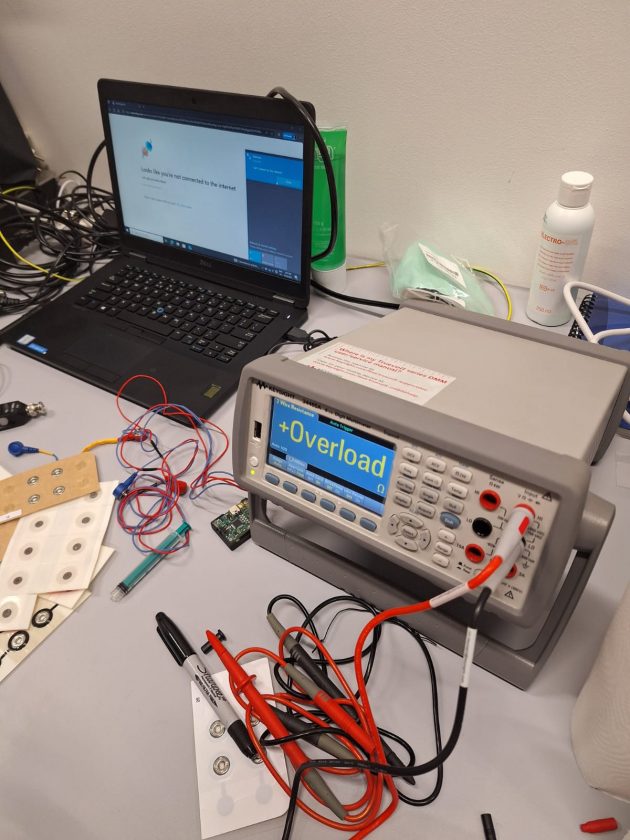

Thirdly, Klara performed practical measurements with electrodes. Bioimpedance was determined over a wide frequency range, electrode surface resistance was measured, the chemical composition of hydrogels was studied using spectroscopy methods, and even participated in MRI (magnetic resonance imaging) protocols to understand the safety aspects of materials and devices in a magnetic field.

Daily work was supplemented by literature analysis and data processing to compare the materials and coatings used in the SUSTRONICS project with the solutions described in international literature, with particular attention to coating uniformity, adhesion, and moisture sensitivity.

The trip gave Klara new practical skills and data that will help improve the electrodes developed by EDI. It can be concluded that more precise coating preparation procedures need to be learned to reduce contact impedance and improve long-term signal stability. A better understanding of MXene dispersion preparation and surface treatment with MXene materials was gained in order to find the “golden mean” between conductivity, biocompatibility, and mechanical elasticity. Furthermore, a draft scientific article was prepared, including the Materials & Methods section and initial results, which is currently being supplemented with additional measurement analysis data.

An important conclusion that can be highlighted for the SUSTRONICS project is that a uniform material coating on a flexible substrate significantly reduces electrode-skin contact resistance and reduces noise during movement, which improves parameters that are important in a clinical environment.

The Bionanotechnology Center at Adam Mickiewicz University provided unique access to equipment and skills development. The visit was carried out in collaboration with colleagues from the ESCULAPE project, who provided methodological support in the development of microscopy, material processing, and measurement protocols.

Klara says about her experience: “Two months in Poznań gave me not only access to modern equipment and tools, but also a very inspiring environment and new knowledge in the fields of biotechnology, materials science, and even programming. My supervisors and colleagues were welcoming and open to trying new approaches, which helped us to quickly move forward with testing electrode materials and understand exactly where we needed to improve our processes. I am returning to EDI with a very practical to-do list and a vision of how to make electrodes more stable and user-friendly.”