- The problem in non-destructive testing and evaluation of building materials, particularly, concrete is the need to improve quality control on sites by introducing smarter testing technologies that can adequately characterize the strength properties and the degree of destruction of the material. Especially, this demand is caused by aging infrastructure assets all over the world and the necessity of timely planning for repair or replacement. Traditionally used ultrasound pulse velocity (UPV) meters have limited sensitivity and are not capable to assess destruction processes in the surface layer of concrete by depth by using only this single parameter affected by multiple factors.

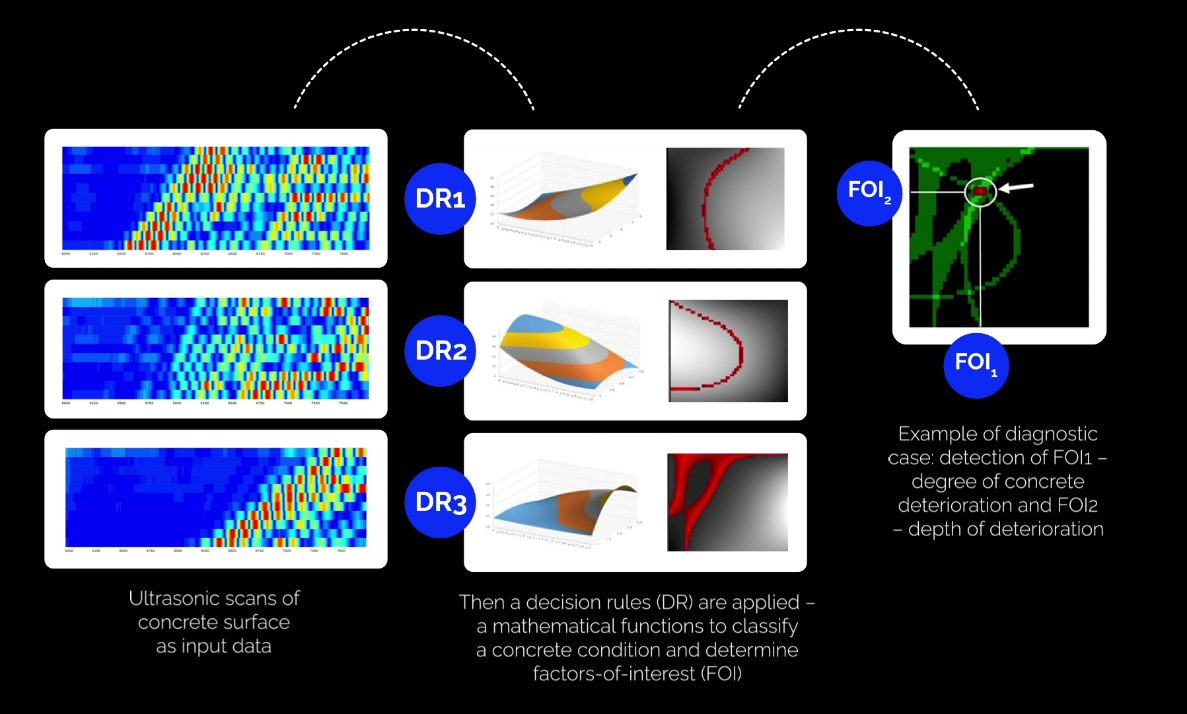

Solution: Ultrasonic surface scanner (USS) is an innovative solution with three innovative technology components in a complex: surface profiling (scanning) and building of 3D spatiotemporal signal matrices as a raw data source; generation of ultrasonic surface waves at different frequencies to apply surface waves spectroscopy; the processing of 3D signal matrices using pattern recognition methods and multivariate analysis. This multi-parametric approach allows a comprehensive assessment of the condition of concrete surface layers and a possibility of analysis of such factors of interest as the degree and depth of the material deterioration.

- Different technologies for quantitative evaluation of concrete conditions in the market. Each of them has its own specialization with varying degrees of versatility, the scope of applications, advantages and the number of limitations or weaknesses. Along with ultrasonic systems, there is a nomenclature of NDT products for concrete, including surface hardness testers such as Schmidt rebound hammer and Windsor probe; resonant frequency testers; impact-echo testers and permeability testing by means of electrical charge measurements.

Ultrasonic techniques are the most widespread for concrete NDT to the class the proposed USS belongs to. The closest analogy is UPV meters produced by the Swiss company Proceq AG and the German company ACS (Acoustic Control Systems) International GmbH. These devices determine UPV, i.e. speed of sound, by surface transmission or through transmission in the material, measuring the arrival time of ultrasonic pulse at the known distance. UPV is utilized to characterize the strength of concrete non-destructively due to empirically obtained correlations between UPV and strength. The application of the UPV method for testing concrete is regulated by several national and international industry standards: ASTM C 597-02; BS 1881 Part 203; ISO1920-7:2004; IS13311; CECS21; ASTM C 597: Standard Test Method for Pulse Velocity Through Concrete; BS EN 12504-4:2004 Testing Concrete. Determination of Ultrasonic Pulse Velocity. The pulse velocity method is an ideal tool for establishing whether concrete is non-unifo, which is a strong reason to presume the degradation of properties on.

- USS technology is unique and original. Its main advantages vis-à-vis close ultrasonic testing technologies in the market are the improved possibilities of a) assessment of the quality of the surface layer of the material in depth; b) forecast of the stage of deterioration, including the early one, associated with the progressing of destructive processes in depth; c) prediction of the material strength based on multi-parametric input; d) discrimination between types of deterioration.

In terms of cost-effectiveness, the USS is a successful trade-off between price and new enhanced capabilities for testing and research. USS takes a middle position by the price between relatively simple, 1-dimensional and “blind” (with no signal viewing and analysis) UPV meters and advanced pulse-echo arrays with imaging.

There is an extremely good opportunity for USS technology to enter the market because the traditional UPV meters have limitations due to their simplified operation principle and the inability to distinguish between important conditions of material, but a new generation of ultrasonic testers based on advanced signal processing has not yet been established. Considering the freedom-to-operate analysis reviewing emerging ultrasound technologies, currently, there are no direct USS analogs and the risk of entry of equivalent products on the market is moderately low.

- An ultrasound surface scanner (abbreviated USS) is a newly developed technology. USS is designed for non-destructive evaluation of the condition of structural materials. USS application is focused on assessing the surface layer of materials most susceptible to the destructive effects of adverse environmental factors and operation. The first and most widespread intended use of USS is testing concrete as the most common construction material. Destruction of concrete pavements and reinforced concrete structures typically progresses from the surface manifesting in cracking, delamination, scaling, destruction of the cement matrix, erosion and disintegration. Adequate assessment of the degree of deterioration and identification of its type are important to plan appropriate repair and replacement strategies.

The total benefits of the USS scanner are advanced diagnostic information, improved sensitivity and specificity for the main interest factors in the assessment of conditions of concrete, lightweight, portable, easy to use, without harmful radiation, without disposables, cost-effective.

- The main technical innovation of USS is the use of multi-frequency 2D spatiotemporal ultrasonic waveform profiles obtained by step-by-step (profiling) of the surface of the examined material for the versatile evaluation of the quality of its surface layer to a certain depth. It is necessary to perform measurements at multiple frequencies in order to obtain ultrasound propagation in the surface layer of concrete at different ultrasonic wavelengths. The surface scanning or profiling allows the following two main propagating wave modes identified as longitudinal sub-surface (head) and surface Rayleigh waves. The first wave is the fastest component with the prevalence of longitudinal oscillations, while the surface Rayleigh wave propagates about two times lower and has the prevalence of shear displacements. Since the waves interfere between themselves and with possible reflections from the bottom of the object, scanning is necessary for proper identification and further processing. In the case of thin layers of concrete where the thickness is smaller than the wavelength, low-frequency ultrasonic waves are guided waves of Lamb type, where the velocities depend on the thickness. The complex processing of multi-frequency 2D spatiotemporal waveform profiles results in the determination of temporal, energetic and spectral ultrasonic parameters and the application of pattern recognition. Based on this, a versatile non-destructive assessment of the mechanical and structural properties of the material and a characterization of the material condition in a whole are made.

- Bildes:

Example of deterioration of concrete infrastructure under environmental factors (a fragment of the newly built Southern Bridge in Riga after several summer-winter periods)

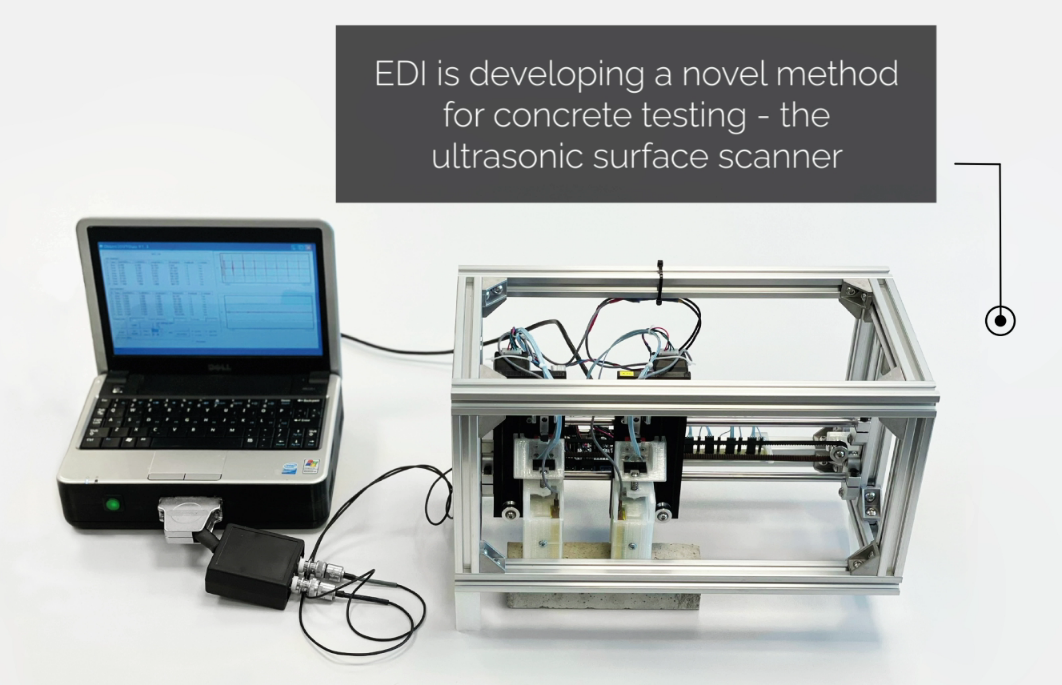

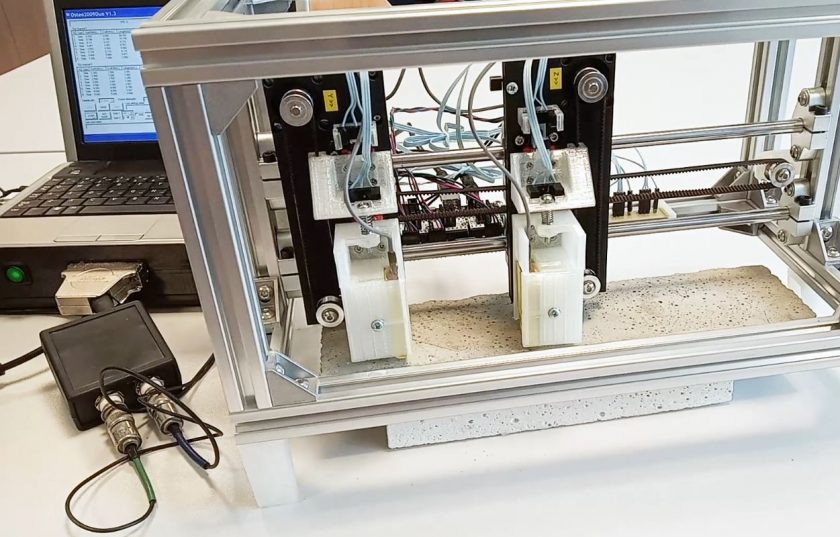

The experimental ultrasonic setup of EDI for laboratory studies approving the USS concept (TRL4 prototype)

Illustration of the application of the pattern recognition approach for evaluation of the factors of interest FO1 – degree of concrete deterioration simulated by a poor cement content and FO2 – depth of deterioration or the thickness of weak surface layer.