European Regional Development Fund Operational Programme “Growth and Employment”. 1.2.1. specific support goal “To increase Investments of Private Sector in R&D” ; measure 1.2.1.2. “Support for Improvement of Technology Transfer System”

Project “Contacless ice thickness measurement device” (EDI-ICE) Nr. KC-PI-2020/40

Agreement with Investment and Development Agency about participating in Technology Transfer measure Nr. KC-L-2017/14

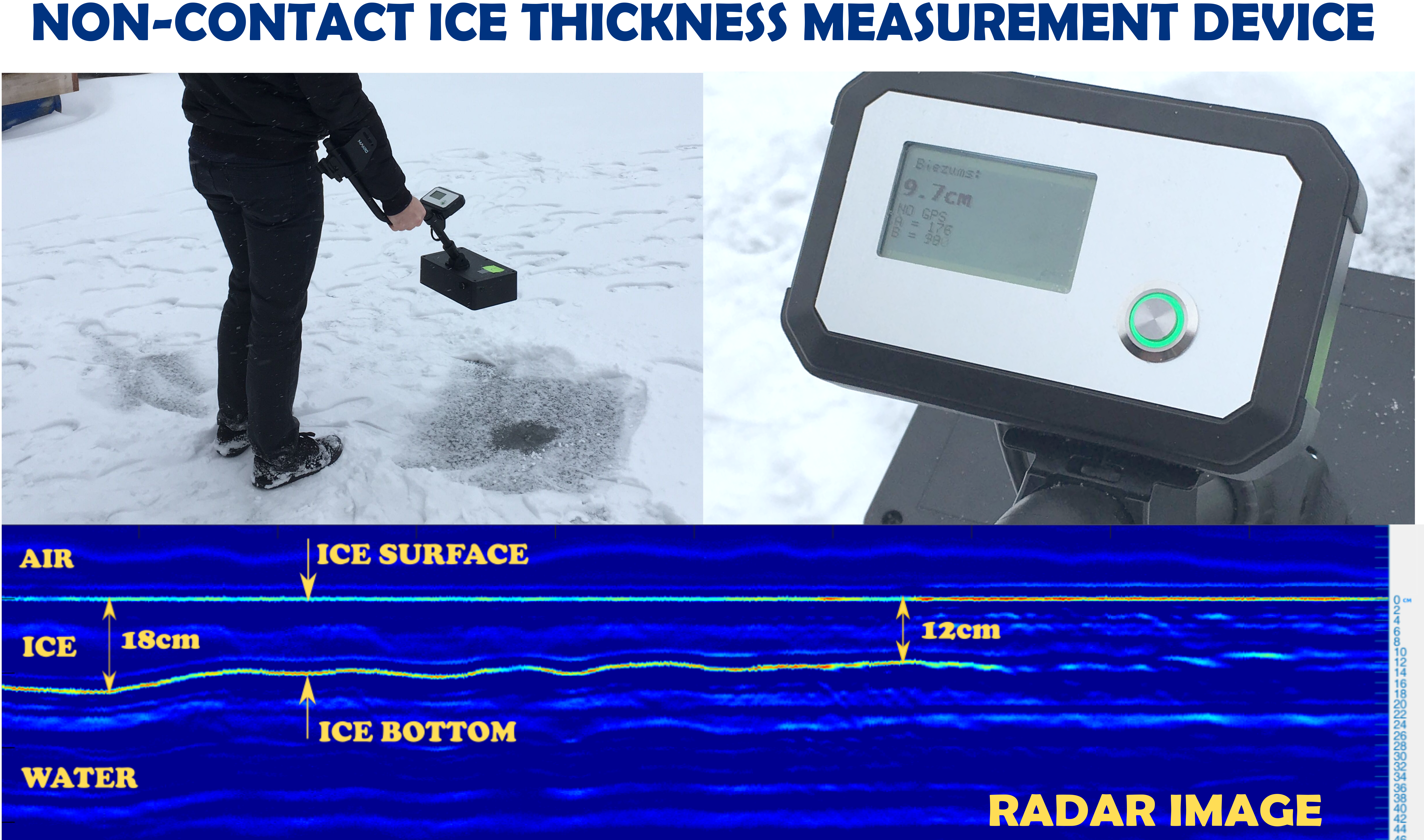

Project goal – Commercialize non-contact ice thickness measurement technology.

Project tasks (broken down into two activities):

- Technology research and development activities:

- Perform (two stage) testing in real conditions during the time when water bodies are covered in natural ice.

- Improve the measurement device by improving both the circuitry and the programming, as well as its ergonomics.

- Develop a specialized application for the user, that would ensure maximum efficiency of the equipment application and return on investment.

- Verify the compliance of device with the EMI norms.

- Commercialization activities:

- Prepare and promote commercialization offers.

- Participate in trade fairs and exhibitions / virtual expos.

- Prepare license / sales agreement and negotiations, FTO search.

Demo site: https://ice.edi.lv/

Reference to the first phase of the project: https://www.edi.lv/en/projects/contactless-ice-thickness-measurement-device-edi-ice/

Total financing of project: up to 250696.21 EUR, included ERDF financing up to 225626.59 EUR.

In the period from 01.06.2022. until 31.08.2022.

accomplished:

Technologies in research and development activities: (01.06.2022 to 31.08.2022)

- Development, assembly and testing of the contact type (<1GHz) antenna and antenna housing for the ice thickness gauge was carried out.

- Compilation of the necessary data for the development of prototype parts of the ice thickness gauge (antenna modules, housings, test stands) and creation of technical documentation was carried out.

- Developed test bench software.

- The improvement of the antenna test stand’s graphical user interface (GUI) has been carried out – the development of the algorithm for the automated recording and display of antenna diagrams.

- Enhanced functionality of the linear bench software.

- Development of automated linearity and measurement error detection software for ice thickness measuring equipment was carried out.

- The development of software for storing the obtained data in the controller of the embedded system, adaptation to the system, debugging continues.

- Debugging and customizing the Python data storage script for the system.

- Improving mutual communication between the embedded system and the storage controller.

- Customization of the software for the system and debugging for storing the acquired data in the embedded system controller continues.

- Debugging and customizing the Python data storage script for the system continues.

- Debugging the intercommunication between the embedded system and the storage controller.

- Completed customizing and debugging the software for the system to store the acquired data in the embedded system controller, as well as debugging and customizing the data storage script for the system.

- Performed final tests debugging mutual communication between the embedded system and the storage controller.

In commercialization activities:

- Several calls with the Finnish partner to better understand the specifics of the use case and possible technical solutions.

- It was decided to conduct additional tests with larger antennas in one of the local ice rinks.

- Searching for new potential leads on the Internet and LinkedIn platform.

- Supplementing the EDI ICE website.

- Remote networking with industry participants at the US GPR Conference.

- The choice of the optimal commercialization tactic was discussed – to hold auctions first, and if no one applies with an offer, then to offer to conclude a license agreement

- Determination of the value of intellectual property was carried out with the aim of defining the starting price of the expropriation for the auction, using the cost method.

- Prepared and described factors potentially affecting the price.

- An auction communication plan has been drawn up.

In the period from 01.03.2022. until 31.05.2022.

accomplished:

Technologies in research and development activities: (01.03.2022 to 31.05.2022)

- Development of an alternative to the existing directional broadband antenna, based on the limitations of the existing prototype housing.

- Creation of a 3D design sketch of a contact-type boat-mounted ice thickness gauge housing.

- Development of an ice thickness gauge demonstration stand.

- Prototyping of a graphical user interface (GUI) (Figma) for displaying ice thickness data on a map.

- Experimental testing of hardware and software compatibility of the next iteration of ice thickness gauge prototypes.

- Development of ice thickness measurement visualization demonstration software.

- Development, testing and implementation of preprocessing algorithms for ice thickness measurement data in GUI.

- Improvement of the cross-sectional (2D) display GUI of ice thickness measurements.

- Addition of additional signal processing tools: CWT, Cesptral analysis.

- Assembly, testing and preparation of the ice thickness gauge demonstration stand.

In commercialization activities:

- Development of project visual materials, one-pagerand website and its content – ice.edi.lv

- Preparing a project presentation for a new LIAA scout. Communication with LIAA scouts and preparation of information for LIAA foreign representations.

- Organization of participation in the exhibition in Germany – application, contract, choice of stand area, etc.

- Planning and organizing a trip to Helsinki to demonstrate EDI ICE technology to potential Finnish partners.

- Participation in the exhibition in Nuremberg (Germany) with an exhibition stand for 4 days.

- Creating a user interface for a technology demo installation for an exhibition.

- Post-processing of exhibition contacts.

- Organization of team meetings.

- Participation with a demonstration stand at EDI days, presenting the technology to DIH World event visitors and other interested parties.

- Planning a trip to the Global GPR Conference in the US.

In the period from 01.12.2021. until 28.02.2022.

accomplished:

Technologies in research and development activities: (01.12.2021 to 28.02.2022)

- Research and development of alternative antennas has been carried out: 1) Contact-type <1GHz antennas, 2) Non-contact >1GHz antennas.

- The design and manufacture of the mock-up board of the battery power connection of the ice thickness gauge prototype was carried out.

- Assembly and testing of components of radar prototype test modules was carried out.

- Established communication between DF Robot A9G GPS module and STM32F469 Disco development tool;

- Completed microcontroller graphical user interface (GUI) prototype – ready minimum product of display representation.

- Created interface between SD card and STM32F469 Disco board LVGL GUI project;

- Added functionality to the test GUI to “playback” experimental data, which allows testing and improving ice thickness estimation algorithms using data collected from previous experiments.

- Experimental laboratory measurements of frozen seawater ice sheets of different thicknesses were carried out using contact and non-contact measurement methods.

- Processing and analysis of the experimental data obtained as a result of experimental testing of prototypes in real and artificially created environments was carried out.

- The porting of the C peak detection algorithm to the existing radar solution was carried out.

In commercialization activities:

Monitoring of industry exhibitions and planning of activities:

-

- decided to participate with a stand at the “Sensors + Test” exhibition in Nuremberg, at the beginning of May, where various sensors and measuring devices are presented;

- decided to take part in the leading US ground penetration radar conference “GPR2022”, which will take place in Denver in mid-June.

- Communication with Finnish partners about the visit and demonstration experiment in Finland under real ice measurement conditions. It has been decided to organize it in the spring – in March or April.

- Creating and presenting mock-upsof various product functionalities to potential partners.

- Preparation and coordination of procurement for the evaluation of the intellectual property created in the project, as well as for the preparation of the patent of the technology created in the project.

- Preparation of presentation materials, market and competitor research.

- Updating and revising commercialization scenarios.

The project and technology were presented to LIAA foreign economic representatives.

In the period from 01.09.2021. until 30.11.2021

accomplished:

Technology in research and development activities:

- Created and ordered component lists for the next iteration of the prototype.

- The drawings of two versions of the prototypes of the structural fastening parts were created and the models of the plastic parts prepared for 3D printing were exported: handles, screen module fasteners.

- Collected, organized and shared with team members technical documentation and Solidworks CAD files for the development of prototype bodies.

- The development of the graphical interface (GUI) firmware of the data processing and display module (embedded system) was carried out according to previously developed sketches of interface prototypes.

- Custom stepper motor control communication protocol for test benches.

- Performance testing and debugging of the test bench control software was performed.

- The test bench management software has been modified according to the principle of modularity, so that it is independent of the addition of add-ons.

- Experiments on determining the thickness of ice imitation concrete slabs of different thicknesses were carried out using the existing version of the ice thickness prototype.

- Preparations have been made for the extraction of frozen seawater ice sheets of different thicknesses and experimental thickness determination using the existing version of the ice thickness prototype.

- Connection of electronic parts of prototype test stands and preparation for development of control software and experimental testing were carried out.

- Processing and analysis of the experimental data obtained as a result of experimental testing of prototypes in real and artificially created environments was carried out.

In commercialization activities:

- Participation in the exhibition “Sectech Expo & Seminars Sweden 2021” in Stockholm (Sweden) (October 27-28, 2021). “EDI-ICE” technology was presented to company representatives and representatives’ contacts were obtained, companies and their representatives were identified for further discussions and exchange of materials on the possibilities and functionality of “EDI-ICE” technology, as well as possible cooperation in commercialization.

- Communication with Finnish partners with whom an NDA is concluded.

- Communication with Russian partners with whom the NDA is also signed.

- Communication with the Science Council of Canada, which is partly responsible for promoting the development and adaptation of innovative technologies for various ice road measurement instruments.

- Cooperation with foreign representatives of LIAA (Sweden, Finland, Norway, USA, Russia) continues.

In the period from 01.06.2021. until 31.08.2021.

accomplished:

Technology in research and development activities:

- Work continues for the hardware development of the next prototype iteration of the ice thickness gauge equipment.

- Manufacture and experimental testing of ice-imitation concrete slabs of different thicknesses was carried out using the existing version of the ice-thickness prototype.

- Preparations to prepare artificially obtained (frozen) samples of sea ice chunks continued.

- Completed concept sketches of modular radar prototype module housings and mounts.

- The technical drawing of the housing of the prototype power (Li-Ion battery) unit has been created.

- The technical drawing of the electrical connection part of the battery block and the radar prototype has been created.

- Research and sketching of antenna options for the next iteration of the ice thickness measuring equipment prototype has begun.

- Revised, organized and debugged the existing prototype firmware code for the thickness gauge.

- The bootloader protocol of the modules closed in the cascade of the modular ice thickness gauge was created and its testing was carried out using the available development tools.

- Started creating firmware documentation using Doxygen tool.

In commercialization activities:

- Technology demonstration (physical or virtual).

- Preparation of marketing materials including test results

- Communication with Scandinavian partners about possible commercialization and cooperation models.

- Communication with industry representatives from Russia regarding saltwater ice measurement.

- Cooperation with foreign representatives of LIAA (Sweden, Finland, Norway, USA, Russia) continues.

In the period from 01.03.2021. until 31.05.2021.

accomplished:

Technology in research and development activities:

- Contact-type ice thickness measurements were carried out in Ķīšezers lake with the existing EDI-ICE ice thickness meter concept test prototype.

- Adaptation of Radar prototype firmware and microcomputer software for drone use-case validation.

- Non-contact ice thickness measurements were carried out in Kīsezers lake with the existing prototype of the EDI-ICE ice thickness meter mounted on a flying platform (quadcopter).

- Collected technical details of the first (proof of concept) prototype of EDI-ICE.

- The data of previously performed experimental measurements were collected and their post-processing was carried out.

- The initial ice thickness measurement algorithm has been improved based on previously obtained real environment and artificially realized environment data.

- A new ice thickness determination algorithm was developed and tested on previously obtained experimental data.

- Improving the Python GUI. Added new options to the existing Python GUI: display processed data and display B-scan.

- Hardware development for the next prototype iteration of the ice thickness gauge equipment has begun

- Concept development and material selection of the next prototype iteration of the ice thickness gauge equipment began. Concept sketches of modular radar prototype module housings and mounts have been created.

- The selection of the mechanical components of the ice thickness gauge calibration (linear) bench and the creation of the housing drawings in the Solidworks environment were carried out.

- Designed and manufactured (3D printed) prototype module fastening elements for various boxes

- Preparations have been made for experimental measurements of artificially prepared sea ice thickness

- An ice imitation stand has been created, in which concrete slabs without reinforcement are used as ice imitation.

In commercialization activities:

- Technology demonstration (physical or virtual).

- Preparation of marketing materials including test results

- Communication with potential customers. Creating feedback with customers and users to improve the functionality and usability of the product – defined 2 product types for different market segments, defined their functionalities and technical parameters, received the first validation from potential cooperation partners.

- Cooperation with foreign representatives of LIAA (Sweden, Finland, Norway, USA, Russia). Both parties signed an NDA with the Finnish company.

In the period from 01.01.2021. until 28.02.2021

- Compiled hardware, software and firmware installations of applicants.

- Preparation of the existing prototype – a portable device for testing in real conditions.

- Functional testing of the prototype was carried out in laboratory conditions (EDI premises).

- Improvement of the hardware, firmware and software of the existing prototype was carried out.

- A methodology for conducting experimental measurements has been developed.

- Adaptation of the data processing algorithm to the existing EDI-ICE prototype was carried out

- Experiments were carried out to measure the ice thickness of Lake Ķīšezers, under different climatic conditions, on Ķīšezers lake and Lake Bābelītis.

- The obtained measurement data were processed, and conclusions drawn, the necessary hardware and software corrections were collected.

- Improvement of the ice thickness measurement methodology was carried out.

- Conceptual validation of the use case of the drone was carried out together with the Riga Municipal Police.

EDI ICE technology was successfully commercialized on March 29, 2023 by signing a non-exclusive license agreement. Since this was a non-exclusive license agreement, the technology is available to others. If you are interested in this technology, please contact us at: info@edi.lv.