European Regional Development Fund (ERDF) programs “Growth and employment” Specific Support Objective 1.2.1 “Increase private sector investment in R&D” Measure 1.2.1.2 “Support for the improvement of the technology transfer system” project “Industrial Inertial Wireless Sensor” (IIBS) identification No. KC-PI-2020/58. Agreement with the Latvian Investment and Development Agency (LIAA) on participation in the technology transfer measure No. KC-L-2017/14.

Background

Various analog solutions for monitoring concrete structures have been available for many years, but they are not easy to use. Also traditionally this is a time-consuming process and construction company employees usually have to come to the construction site in order to carry out specific measurements or to read measurements generated by various sensors. There are also different other technologies besides our technology, but those are not accurate enough. Construction technologies are receiving new contracts and the competition is also increasing rapidly. It is clear that winners will be those companies that will integrate modern smart construction IoT technologies – in order to gain the opportunity to save their own resources and to increase competitiveness. The whole global market of the construction sector is also growing very fast – especially in the sector of industrial objects.

The EDI solution to monitor concrete behavior and shrinkage fits perfectly into the general process of construction digitization, which is currently very relevant for all construction industry companies all over the world.

The main target

The main target is to develop a modern IoT solution – to secure wireless communications between sensors that can monitor concrete structures, concrete hardening, shrinkage process and handheld end-user equipment. This includes the creation of a convenient graphical interface design and the ability to use the solution remotely via a cloud server when responsible persons are located in the company office.

The main tasks of the project

First of all, in cooperation together with experienced potential customers, the technology requirements of the new solution will be clarified. We will create and test various IoT solution prototypes. Software modules will be developed and tested to ensure the collection and processing of data from various sensors and machine learning algorithms will be developed and integrated. One of the main tasks will be to ensure the long-term operation of the device in low power consumption mode and using Bluetooth communication protocols. The device will be operational for a period of about one year. It should be noted that only small rugger modules may be fixed into concrete. The final product will be able to be used through a cloud server, thus significantly saving the resources and time of construction companies to control the concrete hardening processes in real-time and remotely from the construction site. In principle, sensors selected by EDI specialists can also be installed on the surface of concrete, thus monitoring construction during a long time span. From an economic point of view, this state-of-the-art IoT solution will be patented and marketed and sold. Of course, the EDI scientists are ready to customize the solution before/after selling – depending on the specific needs of the construction company that will use the solution.

Activities implemented in the project

Time period: 01.01.2021 – 31.03.2021

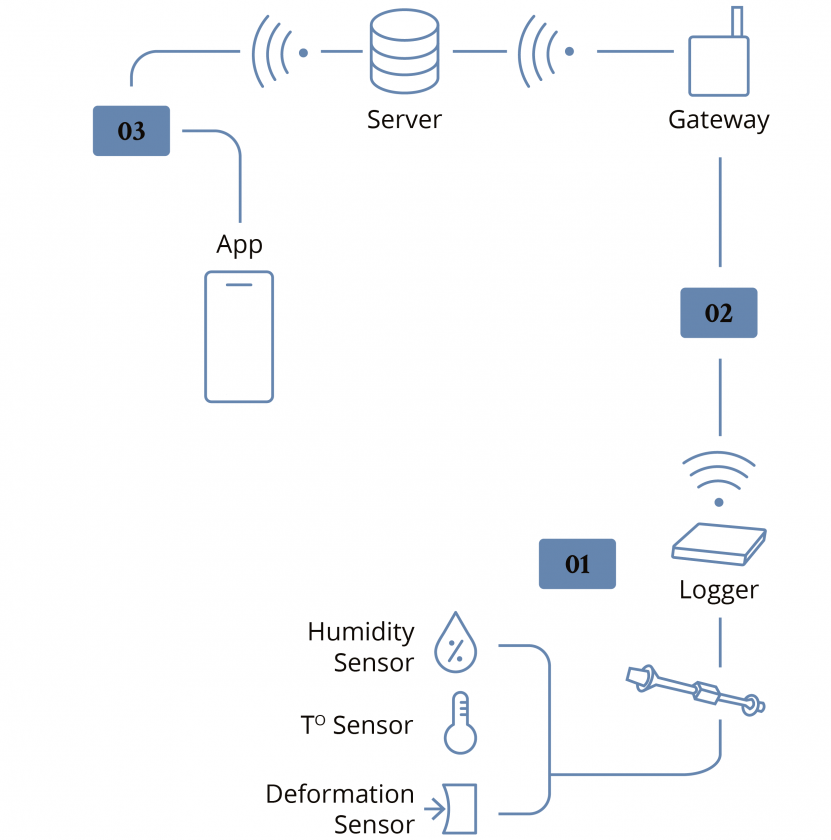

During the first three months of the project, based on the feedback received from the construction companies, the requirements were refined and the overall system architecture was developed for the freshly poured concrete curing process monitoring device – “IoT Platform for Real-Time Monitoring of Concrete Curing Process”. The overall system architecture consists of the following elements:

- sensors measuring moisture, temperature and deformation of the concrete;

- slave devices that acquire data from the sensors and transmit it to the gateway via a wireless connection;

- a gateway (master device) that transmits the data from multiple (up to 256) slave devices via a wireless connection to a server;

- a server that stores and processes the acquired data;

- an application (on the Android phone or on the PC) that processes and visualizes the data in real-time.

A block diagram of the system architecture at a high abstraction level is shown in the figure below:

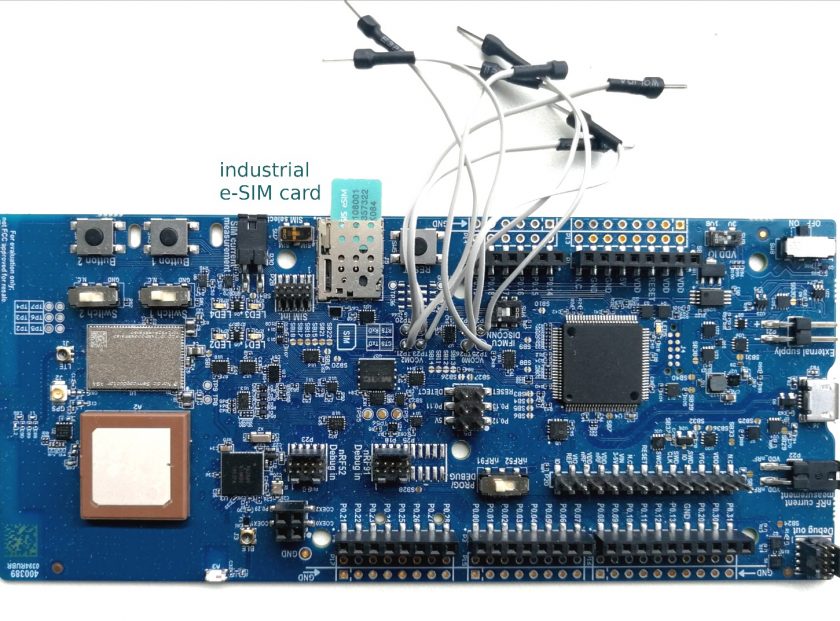

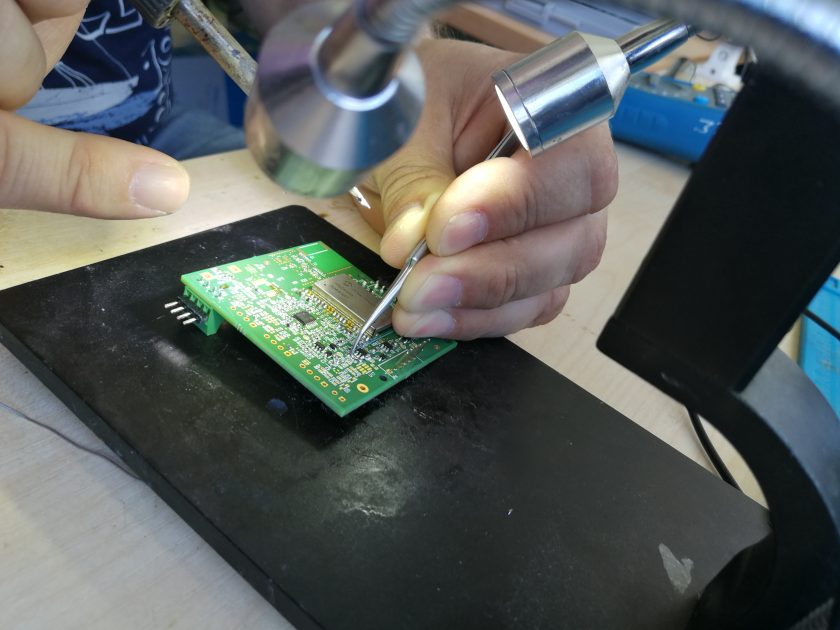

In addition to the development of the system architecture, the design and development of the printed circuit board for the data acquisition module and the development of the software using development tools were initiated. The team also started activities on the algorithms and software development, and the first tests for wireless communication in concrete were done.

In parallel with the technical developments, work was carried out with potential customers to understand their needs and requirements, not only in terms of hardware, sensor accuracy and preferred communication protocols but also in terms of the software solution. A presentation describing the overall system was also developed to make it easier to show the solution to potential stakeholders/customers.

Time period: 01.04.2021 – 30.06.2021

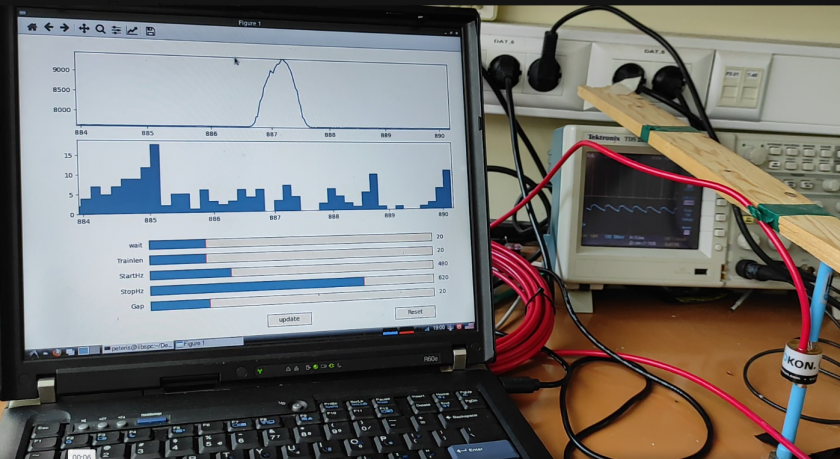

During this quarter, in-depth research in the field of sensors was carried out with the aim of selecting the most appropriate sensors to meet the quality, accuracy, performance and price requirements of the construction industry. Particular attention was paid to the research of a humidity sensor, as this solution was not available in the industry at the time. In-depth research was also carried out in the area of wireless communication technologies: a comparison was made between different wireless commutation modules taking into account the information from the scientific literature about signal propagation in concrete at different concrete moisture contents. Based on the acquired knowledge, appropriate communication modules were selected and a suitable communication protocol was developed for a wireless network between the slave device and the gateway.

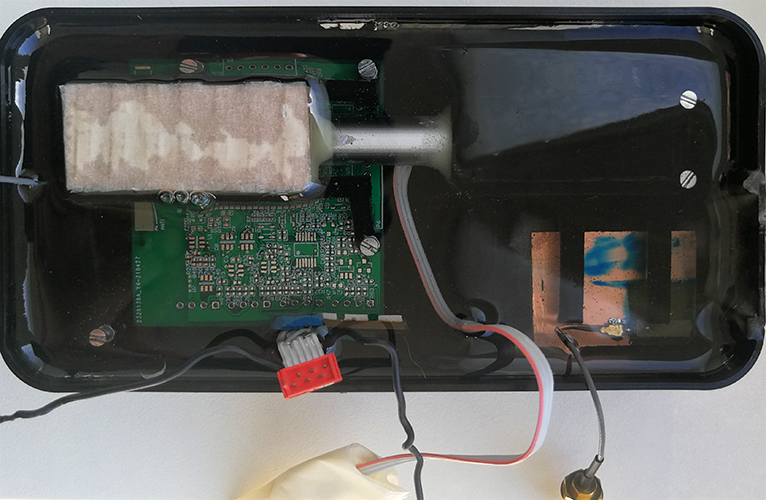

The first version of the sensor data acquisition (the slave device) printed circuit board was designed and commissioned. Different technical solutions were analyzed and a platform (development tool) was selected on which to build the hardware for the gateway. The implementation of the wireless communication protocol in the slave device and the gateway has started. Service filtering was created for the gateway, the ability to connect multiple devices simultaneously and the device pairing function was installed.

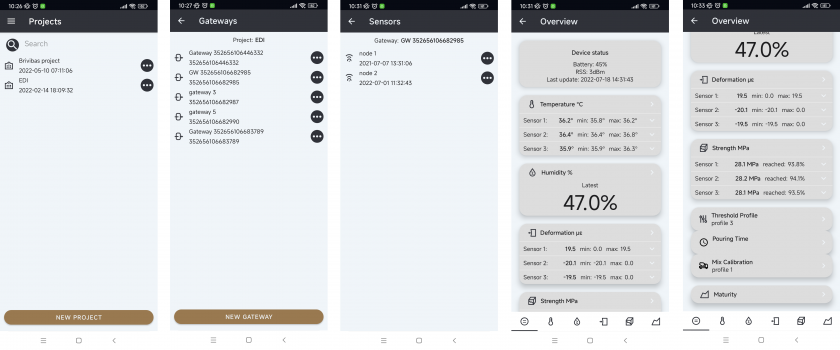

In parallel, while it is not yet possible to obtain data from real sensors, an MQTT broker was created on the EDI local area network server, and the operations and security specifics of this particular broker were explored. The first version of an Android application has been developed, which is able to track data coming into the server in real-time.

Several companies were identified that are dealing with concrete casting and measurements both in Latvia and abroad. These companies were contacted and IIBS technology was presented to obtain feedback and find opportunities for cooperation.

Time period: 01.07.2021 – 30.09.2021

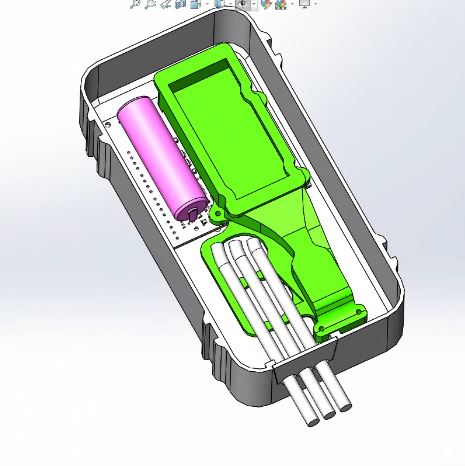

During this quarter, in-depth research on humidity sensors continued. As no such solution existed on the market, the decision was taken to develop our own solution for the humidity measurement cell, i.e. using an epoxy-coated sensor with a ceramic layer. Different approaches to moisture measurement were developed and several tests were carried out in alkaline concrete environments. The first version of a slave device housing with an integrated humidity measurement cell was built and the first tests and measurements were carried out.

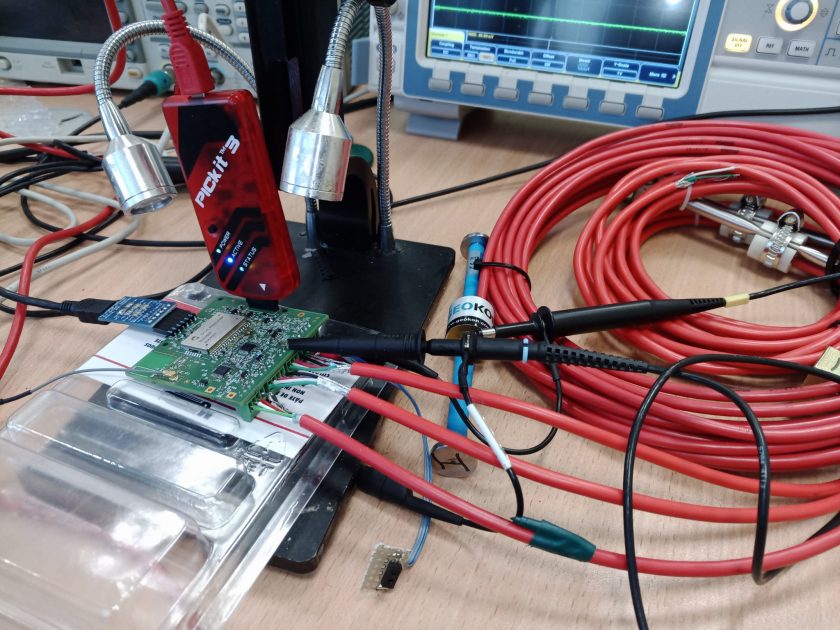

A software solution was developed to measure the deformation using a specific microcontroller. By connecting strain sensors to the slave device and simulating concrete deformations, the first measurements and tests were carried out, which allowed the finetuning of the associated analog part. In addition, a multi-channel measurement approach was developed. Based on the measurements and tests obtained, the next version of the slave device was designed and developed, optimizing the different elements and components in the system. Testing of the new version of the slave device was done.

The gateway module development continued. The team was working on the gateway algorithm and the communication protocol with the network nodes. A state machine was developed to allow communication, measurements and slave device sleep to be organized in time.

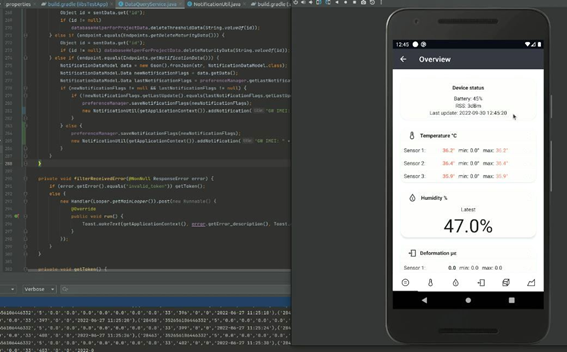

The database server was designed and improved, and a database programming interface (including authentication and data transport) was developed. Also, the Android application was developed to use this interface. Scripts were written on the server to create and check data structures for the database service. User information stacks were added to the database service and the scripts for adding and editing their information were adapted accordingly. Software development for sensor measurements on the peripheral controller was done.

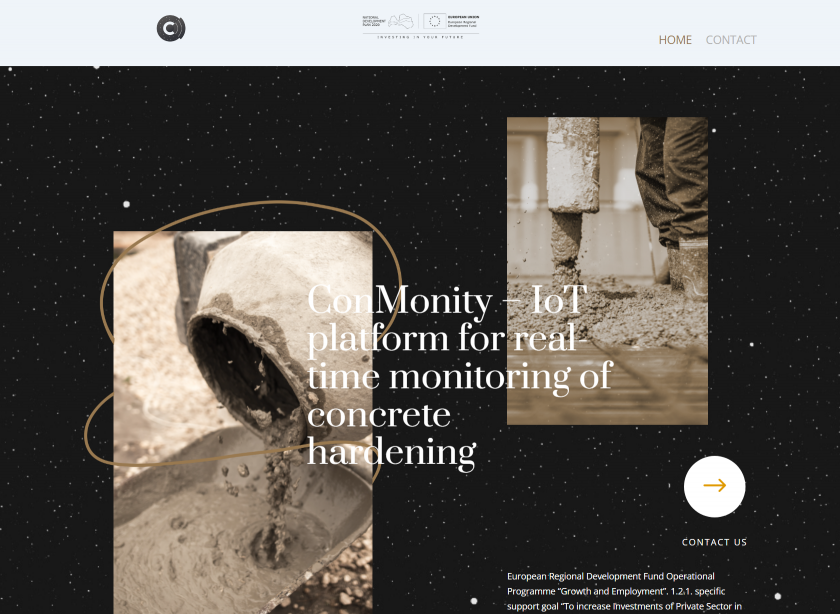

The design of the exhibition stand was developed, as well as the logo and visual identity – the technology will be called ConMonity. A one-pager was developed to inform potential customers. Some video on the technology was also produced. In addition, a number of companies were identified as the potential buyers of the intellectual property and responsible person contacts were found who exactly should be approached. New competitor solutions were identified. Exhibitions and events were also identified at which it is possible to present the technology in the near future. Communication with potential customers was continued and the first version of the IIBS technology website – https://conmonity.edi.lv/ – was developed.

Time period: 01.10.2021 – 31.12.2021

Our team continued to test the slave device housing or humidity measurement cell with temperature and humidity cycles in an industrial climate chamber located in EDI. Strain measurements were also performed and challenges with signal distortion and increased noise levels were addressed. Testing of different solutions at the prototype level was carried out.

Development of a gateway PC simulator for testing algorithms and the node scheduler. Different possible antenna implementations (magnetic or electric antenna) were compared. Measured the parameters of the antenna in composite and the antenna in the air. Tests related to the antenna performance (parameter changes) in eposcide were performed. The functionality of the node timer was improved. The modem command system of the node was extended. Further development of the gateway emulator PC was performed. Scripts were also developed for the server for filtering and logging notification data for the database service, as well as for the end-point for extracting notification data.

Integration of the ML model into an Android application for QR code scanning. The QR code information structure was developed. Further development of the web administration panel was done. Work started on the design of the GUI (graphical user interface).

Identification and communication of potential cooperation partners in Latvia continued. We were participating in various online events to obtain better commercialization results. Updated marketing materials, and sales presentation, and improved one-pager in terms of design and content. The commercialization expert participated in the GITEX exhibition, preparing the corresponding photo and video material. As part of the market research, the participation of various construction companies in exhibitions in Europe and the USA was studied. Potential customers in different countries were sought. The intellectual property portfolio was defined. A webinar was organized and content prepared – the creation of an event landing page, sending of emails, and creation of visuals were carried out accordingly.

Time period: 01.01.2022 – 31.03.2022

Research and relevant developments were done aimed at improving the accuracy of sensor measurements. Circuit changes were made to the design of the peripheral printed circuit board. Optimization of the printed circuit board was also carried out. In addition, laboratory tests of the string sensor and optimization/improvement of the data acquisition circuit as well as adaptation and optimization of the peripheral firmware were performed. Temperature and humidity sensor tests and optimization/improvement were also performed.

Script development for the server for filtering and logging notification data for a database service was done including script development for endpoint, notification data extraction, server, network data transfer and storage. Also, a gateway code upgrade for network data retrieval and transfer to the MQTT broker was done. The structures and basic functions of the GW-WebAPP API gateway were implemented. Preparation of parameters, and information for design elements of Android application. Continued development of the web administration panel. Created system integration solutions on a cloud platform.

Worked on a patent. Working on the development of the technology description.

Activities to create visual images and color palettes of the technology. Work started on the graphic design of the official website of the project and the necessary text input, and we adapted the design of mobile phone, tablet and desktop views. In parallel, the new ConMonity icon and color panels were integrated into the Android app.

Time period: 01.04.2022 – 30.06.2022

The project solution was presented at the SENSOR + TEST exhibition, which took place from 10 to 12 May 2022 in Nuremberg, Germany.

The different companies participating in the fair were identified, one part was sensor manufacturers, and another part was integrators with their own Internet of Things (IoT) solution. We, in the EDI booth, demonstrated not only the sensors we use but also an Android application (simulation) on a mobile phone where you can see all the layers: the construction project, the gateway and the sensor data. Several companies were identified and information about the ConMonity solution was sent out. A representative video of the system from the app’s point of view was also created:

In addition, the technology was presented during “EDI Day”. Communication with potential customers interested in divesting their intellectual property continued.

The research continued on improving the accuracy of measurements, and gross errors in measurement rejection. The application and implementation of the chosen method were carried out. Software development work has been carried out in the context of incorporating the chosen method into the two-step measurement cycle routine. Work was also carried out on the implementation of a data collector autocorrelation algorithm for use in both the coarse and fine measurement phases. Prototype testing was carried out in conditions to be close to an industrial environment.

The data collector state machine was extended with some new states to allow node module reconfiguration as well as data transfer to the server via the ConMonity Android interface. Further development of the sensor node’s hardware-software: improved scheduler performance and management capabilities, optimized code and memory usage; gateway code updated according to the node’s functionality. Testing and debugging of the complete gateway code was performed by interacting with the MQTT broker and network nodes. Improvement of server scripts for more efficient extraction of network data from the database service and transfer to the gateway. Collecting datasets from target sensors, under realistic conditions. Continued development of the Web administration panel. Development of data computation and visualization algorithms and preparation of patent application document was done.

Time period: 01.07.2022 – 30.09.2022

During this period, work on the ConMonity technology “IoT platform for real-time monitoring of the concrete curing process” was continued and completed. This included the integration of all existing modules into a single solution, and tehir testing and validation. In addition, work was carried out on improving the functionality of all nodes and optimizing energy consumption.

Studies have also been carried out on data acquisition and transmission when the sensors are mounted outside the concrete structure.

The performance of the selected antennas was also analyzed.

As part of our commercialization activities, we took part in an off-site seminar in Valmiera organized by one of the leading construction companies in Latvia. An overview of IoT technology opportunities and trends in the construction sector was given. In addition, ConMonity technology was discussed in depth – how to monitor the curing process of freshly poured concrete in real-time. It was concluded that in the near future all subcontractors involved in the fresh concrete pouring business will be forced to use such technology, but for the time being companies in Latvia are not yet ready to apply such a system in all construction sites, as such requirements are not set by the client requirements.

A video was produced showing how the sensor data is generated and how the information is visualized on the screen of the Android device.

In addition, project staff participated in various public events to demonstrate and explain the ConMonity technology “Internet of Things platform for real-time monitoring of the concrete curing process” in order to find potential customers. For example, the ConMonity technology was presented and demonstrated to participants of the Horizon 2020 project “Digital Technologies, Smart Robotics and Enhanced Cyber Security for Faster Manufacturing in the Future European Manufacturing Ecosystem (TRINITY)” (~15 participants), the Horizon 2020 project “Intelligent Motion Control under Industry 4E (IMOCO4.E)” (~80 participants), and the Institute’s Researchers’ Night (~500 participants). We continued to develop the patent application document.

During this period, auctions were also organized for the possibility to acquire the ConMonity technology.

Time period: 01.10.2022 – 31.10.2022

During this period, the technical activities of the project were discontinued and the main focus was to organize commercialization activities. Apart from actively searching for customers and negotiating with potential customers in Western Europe and China, the project staff participated in the RIGA COMM 2020 exhibition (1000+ visitors). There the ConMonity technology was demonstrated with the aim to find possible potential local customers.

In addition, information on ConMonity technology was published on the Innovation and New Technologies portal LABS OF LATVIA.

The ConMonity technology was successfully commercialized by signing a non-exclusive license agreement on December 12th. As this was a non-exclusive license agreement, the technology is available for other stakeholders. If you are interested in the technology, please, contact info@edi.lv.

Participating scientists

Dr. sc. ing. Kaspars Ozols

Deputy director of development, Senior Researcher

+371 67558161[protected]