Low-priced bolus for monitoring rumen parameters and early diagnosis of subacute rumen acidosis (SARA) in cows

A project co-financed by the European Agricultural Fund for Rural Development (EAFRD) within the framework of measure 16.1 “Cooperation” of measure 16 “Cooperation” of the Rural Development Programme 2014-2020 (RDP) within the framework of sub-measure 16.1 “Support for the implementation of projects of agricultural productivity and sustainability working groups of the European Innovation Partnership for agricultural productivity and sustainability”.

Project number 18-00-A01612-000004

Project lead partner: Riga Technical University

Project partners: Institute of Electronics and Computer Science (EDI), Latvia University of Agriculture (LLU), Cooperation Council of Agricultural Organizations (LOSP), SIA Ogres piens, z/s Zilūži.

The aim of the project is to develop and put into practice an intraruminal long-acting system and method for monitoring rumen parameters in order to prolong the life of high-yielding dairy cows, increase milk yield, detect undesirable changes in rumen parameters in a timely manner and take measures for the prevention of subacute rumen acidosis (SARA).

Planned activities and result: experimental development – production, testing and validation of a prototype of the SARA diagnostic system (pH bolus) in an environment reflecting real-world operating conditions and testing of the system in a real-world environment. The developed system will increase the productivity of the livestock industry, reduce the amount of low-productive work on farms and improve the conditions of animal maintenance.

Development of the pH bolus and its components

Content

-

Brief summary

-

The main components and their selection

-

Implementation of the selected solutions

-

Development of bolus housing and microcontroller boards

- Bolus sealing and testing

-

pH bolus content

1. Brief summary

The development of pH bolus included the selection of their main components, the selection of their interfaces, the detailing of components and their development, the development and debugging of algorithms and software, the development of hardware mock-ups, the design and manufacture of hardware, testing of manufactured modules, operating system recordings, application tuning, bolus preparation, protective treatment, calibration of pH sensors, testing the waterproof of the bolus housing, and collection of pH bolus measurement data.

2. The main components and their selection

The functions performed by the pH bolus unambiguously determine the composition of the hardware contained in it and the necessary software drives. The basic function of the pH bolus is prolonged, regular measurements of pH and temperature in the rumen of the cow and the transmission of data from the measurements taken outside the rumen of the cow at certain points in time. A pH sensor and its interface with the microcontroller are required for pH measurements. A temperature sensor is required to take temperature measurements. A radio transceiver is required for the transmission of measurement data. The microcontroller performs control of pH, temperature measurements, radio and power supply of devices, feeding control signals to the execution. At the same time, the microcontroller reads the values of pH and temperature measurements and stores them in memory. The radio, receiving measurement data and control signals from the microcontroller, performs data transmission. An essential component of the bolus are also a power battery, a power supply unit and power switches.

3. Implementation of selected solutions

The existing restrictions on the implementation of solutions are related to the dimensions of the bolus, which are determined by the purpose of its application, with the capacity of the power supply battery. Therefore, it was necessary to develop a 4-layer compact microcontroller plate on which all elements except the pH sensor would be located. The pH sensor is located on the outside of the bolus and is protected by a bolus sleeve. The switching part of the pH sensor is located inside the bolus. The pH sensor is connected to the microcontroller with a cable. The pH sensor is the most essential and expensive element of the pH bolus with the price 400 euros. The pH sensor consists of an ISFET (ion-sensitive field transistor) device and a reference electrode ET072, which, unlike other reference electrodes, is long-lived, lasts 1-2 years. The initial realization was intended for the execution of modules using a designed modular switching board with a power supply unit.

In such a switching board created to test the concept, one could pin the necessary modules and insert it into the bolus. However, the dimensions of the concept board exceed the permissible dimensions and could not be inserted into the bolus. The concept board was used to check the operation of the pH sensor and radio transceiver.

4. Development of bolus housing and microcontroller boards

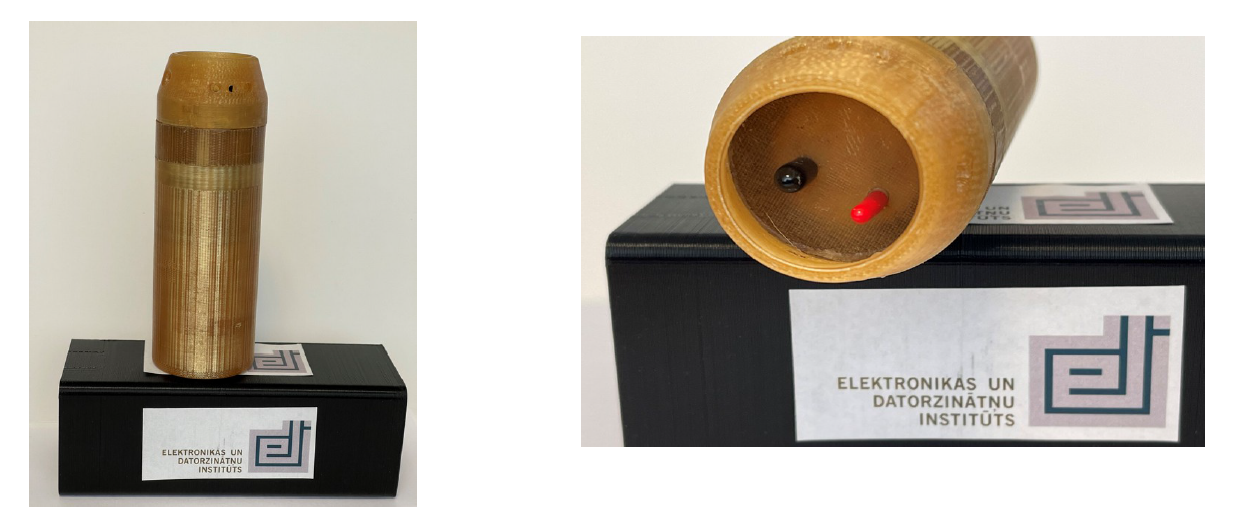

The creation of a bolus case is one of the most important stages of development, since the quality of the case determines its ability to protect the electronic devices used against substances and liquid contained in the cow’s rumen, which is able to oxidize the devices and cause a short circuit of electrical circuits. The development of the bolus hull took place in several stages. At stage 1, the dimensions of the bolus housing were modeled, which would correspond to their application in the rumen of a cow and at the same time correspond to the permissible dimensions of the microcontroller plate and feeding batteries. 2 bolus cases were made of ABS plastic. Their compliance with the dimensions of the plate and the possible position of the pH sensor was validated. At stage 2, 3 real, suitable for use bolus cases were made of PLA plastic. PLA plastic is animal-friendly, unlike ABS plastic. PLA plastic degrades with time, so it can only be used for temporary placement in the rumen of a cow.

Taking into account the results of pH bolus preparation for measurement and temporary insertion, adjustments and changes were made to the design of the bolus body. In Stage 3, 6 corrected bolus cases were made of PEI1010 plastic, which, like PLA plastic, is harmless to animals, but unlike PLA plastic does not degrade. The development of bolus enclosures took place using the SolidWorks software.

The development of microcontrollers with Altium Designer was started after the development, design, layout and testing of the AFE(Analog Front-End) scheme with a pH sensor. A 4-layer microcontroller plate was designed, the following blocks were located on it: 1) a microcontroller; 2) pH sensor interface diagram AFE; 3) a radio transceiver; 4) temperature sensor; 5) radio and pH sensor power switches; 6) power supply unit; 7) power battery.

The microcontroller plate was made in Germany, because in Latvia there is no possibility to make a 4-layer plate. In the first order, 10 plates were ordered, of which, after soldering, 8 were valid for use. When performing OS recordings on plates and checking the operation of microcontrollers, 6 plates functioned normally. Due to the dense track and small dimensions, it was impossible to make corrections with a soldering iron. In the process of testing the board, placing them in the bolus and taking measurements, 5 plates were used. In order to improve the plate, a second microcontroller plate was designed with an improved power supply unit and the shortcomings of the first plate were eliminated. But the other plate was not made, since it was impossible to order chips. In addition, 4 first plates were ordered, in which a power unit developed by RTU was used.

5. Bolus sealing and testing

Initially, the sealing intended for the protection of the bolus against the contents of the rumen of a cow turned out to be insufficient. Repeated tests of the operation of the bolus showed that it is not enough just to hermetize the bolus, but additional protection of electronic devices is required. For this purpose, a general coating silicone sprayer DCA SCC3 and a two-component silicone coating mass 021 were purchased. Their application significantly improved the protection of bolus electronics against the contents of the rumen of a cow. Testing the sealing of the pH bolus took place by placing it in water for 5-10 days. Testing of the pH bolus initially took place in cows with a fistula, which made it possible to promptly insert and remove the pH bolus. Making sure of the normal functioning of the pH bolus in fistulated cows, the pH bolus was placed in the rumen of the cow LLC “Ogres piens”.

pH bolus pictures

6. pH bolus content

The dimensions of the bolus are as follows: diameter – 40 mm, length – 143 mm. In the lower part of the bolus, a section of a copper tube with a diameter of 30 mm, a height of 50 mm, and thickness 1.5 mm is inserted. The copper tube section provides the necessary weight and weight distribution of the bolus. A microcontroller board SESP, radiotransmitter inAIR9B with antenna W3502 and a 2 x 3.6 V AA-sized SAFT LS14500 CNA lithium battery are inserted into the bolus. In the lower part of the bolus there are plugs for the reference electrode ET072 and the ISFET sensor A120-001. In the upper part of the bolus the radio and antenna is located .

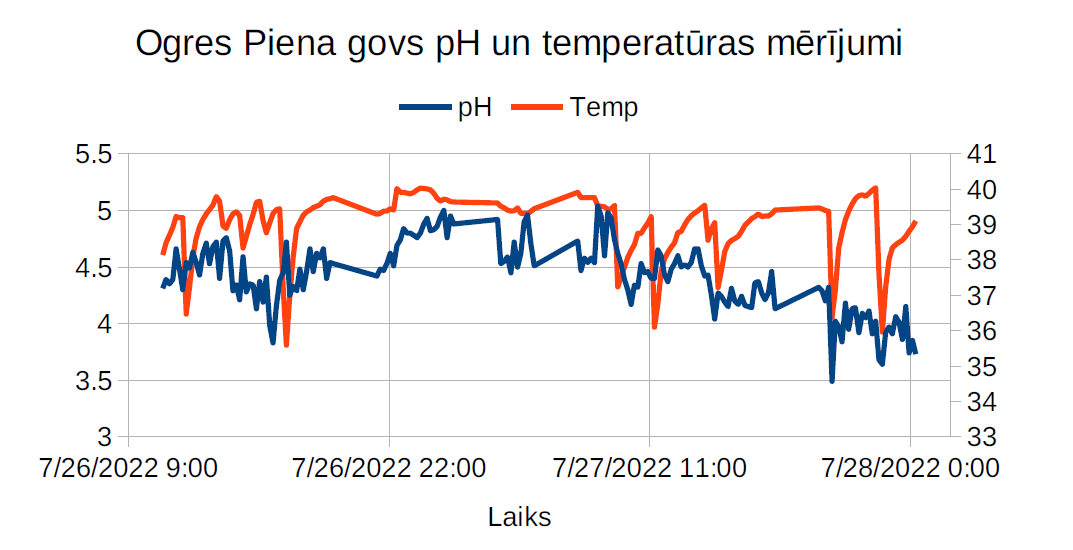

Measurements of the pH bolus inserted into the rumen of a cow of SIA “Ogres Piens”